A steam trap is a device used to discharge condensates and non condensable gases with a negligible consumption or loss of live steam steam traps are nothing more than automatic valves they open close or modulate automatically.

Inverted bucket steam trap working principle.

These are mechanical type of steam traps working on the principle of buoyancy.

Inverted bucket traps.

Discharge condensate as soon as it is formed unless it is desirable to use the sensible heat of the liquid condensate.

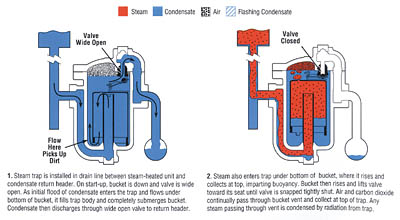

Inverted bucket trap which works on the principle of buoyancy densities difference of water and steam the rising in condensate level fills and envelopes the bucket causing it to sink which open the mechanically linked valve and discharges the condensate and reverse when the level of condensate drops steam enters the bucket causes the flotation of the bucket which close the valve and.

Initially the bucket is resting at the bottom of the steam trap and the valve seat is wide open.

The inverted submerged bucket steam trap is a mechanical trap that operates on the difference in density between steam and water.

As its name implies the mechanism consists of an inverted bucket that is connected by a lever to a valve.

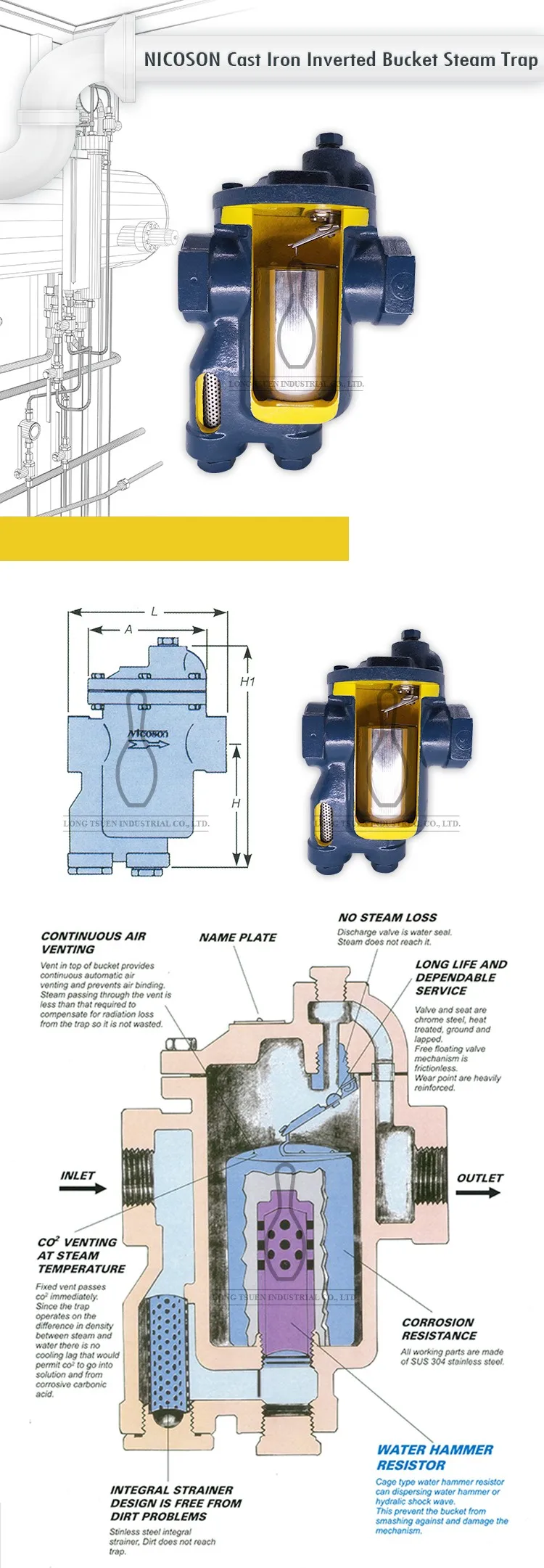

Inverted bucket steam trap mechanical steam traps the inverted bucket steam trap is shown in figure.

Steam entering the inverted.

As its name implies the mechanism consists of an inverted bucket which is attached by a lever to a valve.

The three important functions of steam traps are.

The inverted bucket steam trap is shown in figure 11 3 3.

Inverted bucket steam trap.

When steam or air flows into the underside of the inverted bucket and condensate surrounds it on the outside the steam causes the bucket to become buoyant and rise.

Figure 11 3 3 shows the method of operation.

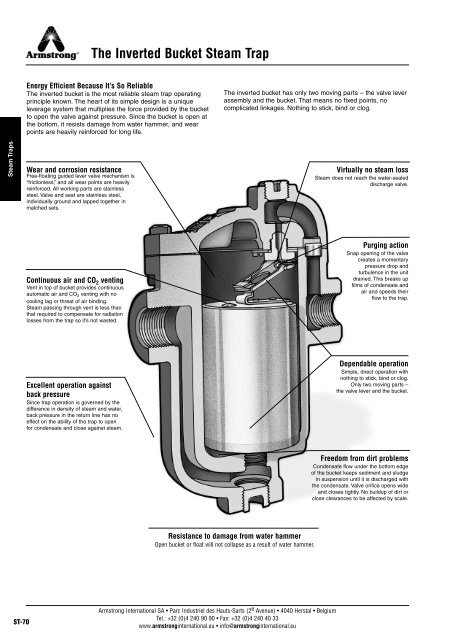

The inverted bucket steam trap energy efficient because it s so reliable the inverted bucket is the most reliable steam trap operating principle known the heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure since the bucket is open at.

In inverted bucket steam traps the bucket within the trap is attached to a lever that opens and closes the trap valve in response to the bucket s motion.

An essential part of the trap is the small air vent hole in the top of the bucket.

The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.