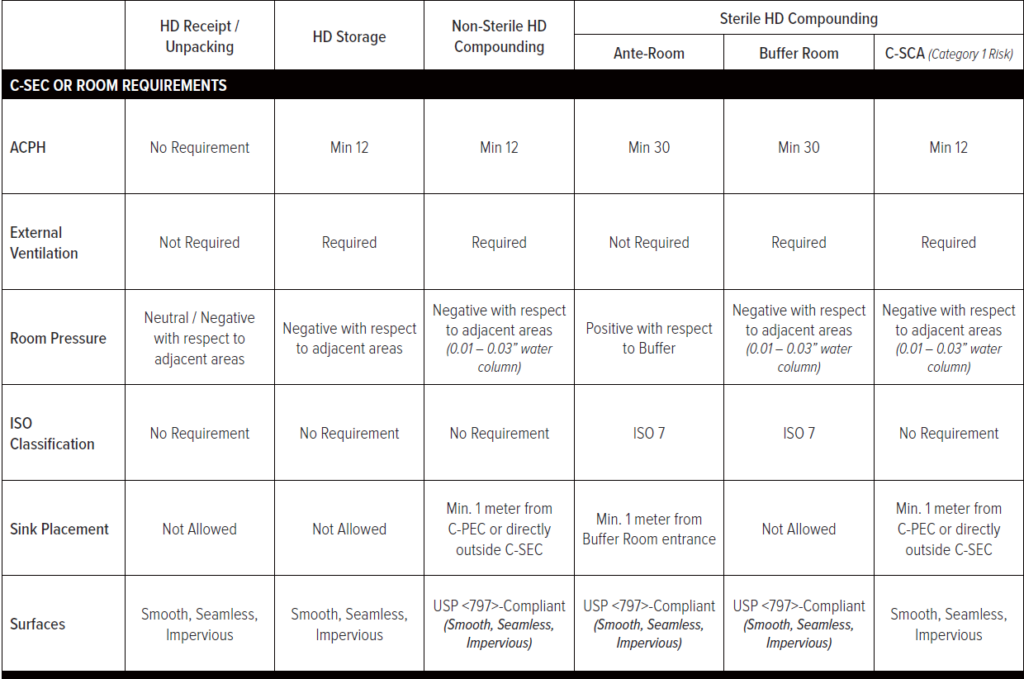

Rate of air exchange is expressed as the number of air changes per unit of time and calculated by dividing the volume of air delivered in the unit of time by the volume of the cleanroom or clean zone.

Iso cleanroom standards air change rates.

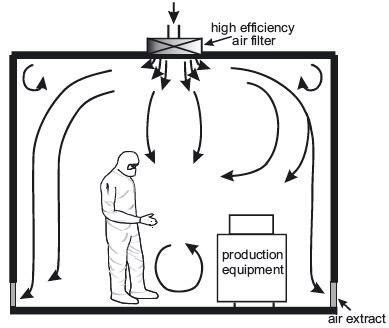

A 30 percent reduction in air change rate results in a power reduction of approximately 66 percent.

Within you ll find summarized approaches for determining cleanroom air change rates but not recommendations.

The air changes per hour will vary in both rooms as described below.

As defined by iso 146144 4 standards.

Fan power is proportional to the cube of air change rates or airflow.

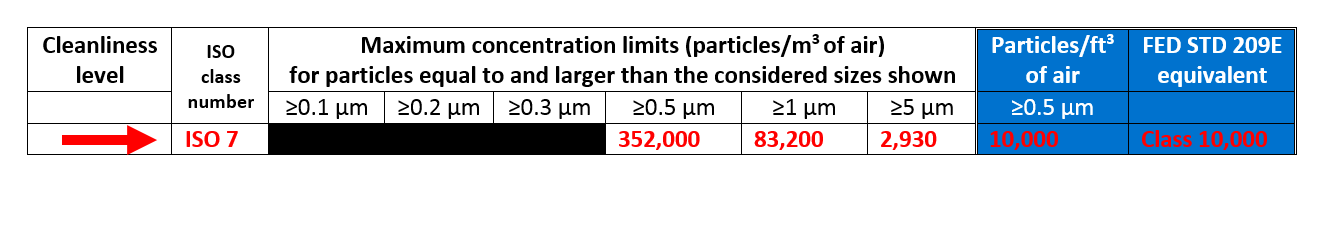

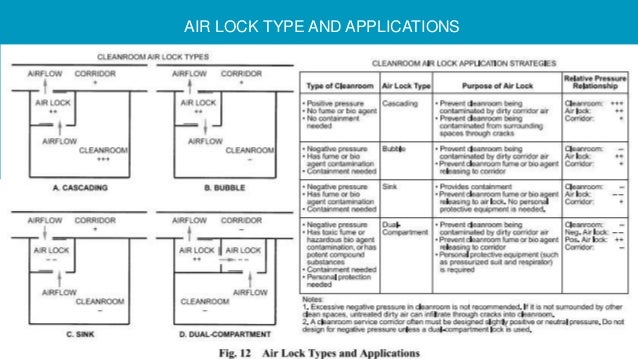

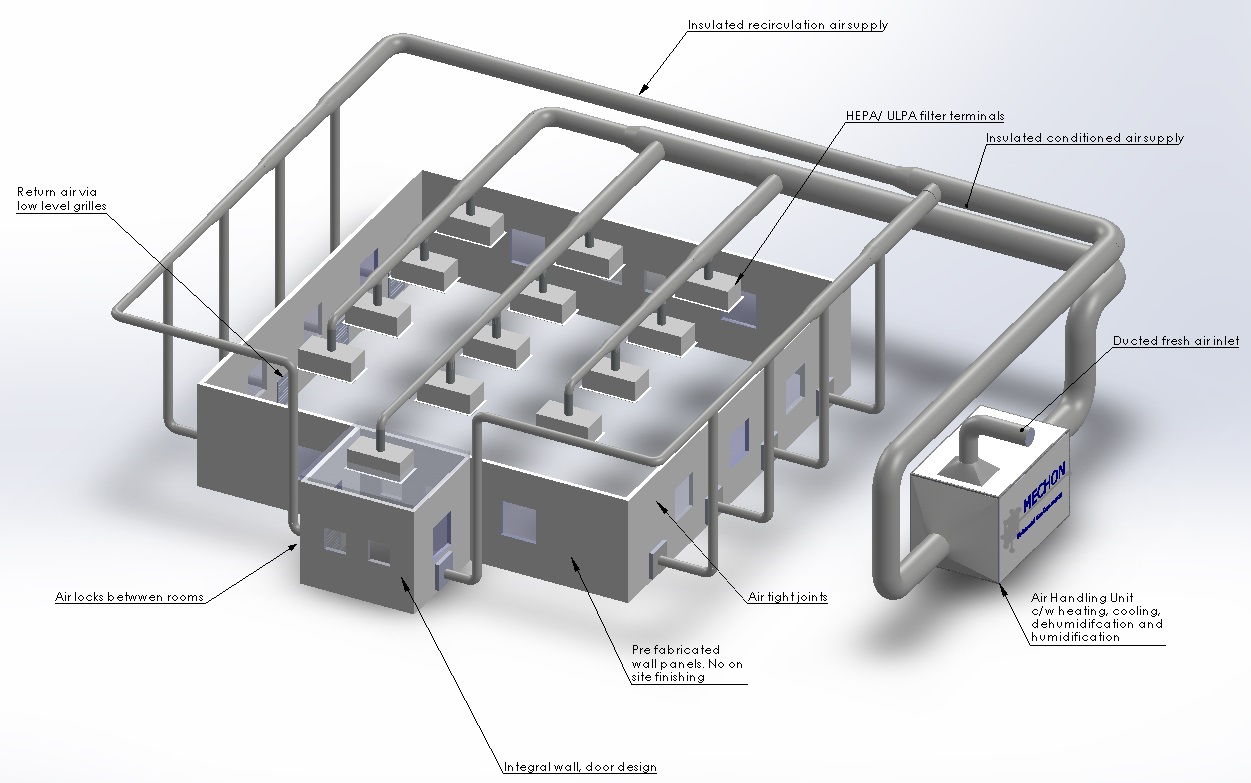

If you need an iso 7 cleanroom you should consider having an iso 8 airlock gowning room prior to entering the iso 7 room.

This is one of the most common classes of cleanrooms.

Iso 8 zone 15 25 air changes per hour ante room.

The study measured air change rates in several iso class 5 cleanrooms and came to the conclusion that there is no consistent design strategy for air change rate even for cleanrooms of the same cleanliness classification acr rates have critical design implications especially when considering desired cleanliness fan size and lower energy costs.

By minimizing turbulence lower airflow may improve cleanliness.

Iso class 8 5 60 air changes per hour with a ceiling coverage of 5 15.

As of november 29th 2001 the federal standard 209e has been replaced with iso 14644 1.

Contact clean air products for cleanroom requirements classifications today contact us for more information on cleanroom standards iso class code descriptions and clean room air changes or request a quote for an in depth price analysis today.

Air changes by cleanroom classification this table details the recommended air changes per hour for iso 14644 1 2015 cleanrooms and their associated gmp grade and federal standard.

Lower air change rates result in smaller fans which reduce both initial investment and construction cost.

Rate of air exchange expressed as number of air changes per unit of time and calculated by dividing the volume of air delivered in the unit of time by the volume of the cleanroom or clean zone source.

Role and calculation of air changes per hour in clean room area determination of the air velocity in cfm and air changes per hour acph in pharmaceutical clean rooms and also know its requirements in different cleanroom classes like 100 1000 10000 100000.

This post addresses air change tables and calculations in iso 2 iso 3 iso 4 and iso 5 cleanrooms with unidirectional airflow.

To meet requirements of a clean room as defined by federal standard 209e and newer iso standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class.